1994 Ingersoll-Rand T4W Drill Rig

Sold

Description

1994 Ingersoll-Rand T4W Drill Rig

Note: Reduced Price as of June 2021

Rebuilt in 2006

Rebuilt Cummins KTA19C Diesel Deck Engine (rated 600 HP at 2100 RPM)

Rebuilt in 2006 a IRH2.5 1070 cfm / 350 psi air compressor

Deck Engine Meter Reads 5,955 hours

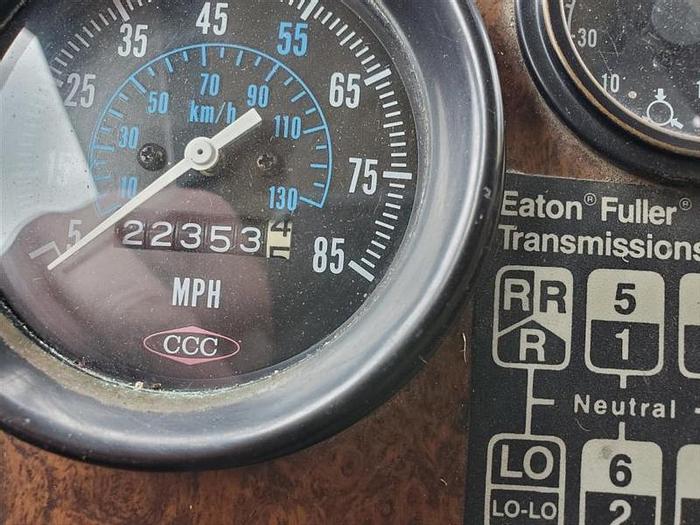

Mounted on a CCC (Crane Carrier)

Cummins L10 diesel engine

Carrier Meter Reads 4,635 hours

Carrier Meter Reads 22,353 Miles

50,000 lbs of pullback

Setup for 2-7/8" IF Drill Pipe

The following work was performed when rebuilt in 2006:

Rebuild of rig and components

Remanufactured Cummins engine KTA19C 600 HP @ 2100 RPM from Cummins

(upgraded from original 545 HP @ 2100 RPM)

Remanufactured IR compressor HR2.5 1070 CFM @ 350 PSI

Rebuilt funk box Rebuilt or new hydraulic pumps and motor

Rebuilt hydraulic cylinder All new hydraulics and air hose

New and upgraded radiator

New and upgraded air compressor, oil cooler and hydraulic oil cooler

Valve spool rebuilt – new seals and control handles

New feed chains upper and lower – Upgraded

New front leaf springs on carrier

New gauges

New wire harness

Rig and all parts sandblasted and painted grey and red

Rig completely serviced – Ready to drill

Additional tooling:

6” IR QL60 Drive Hammer with Bit

6” IR QL60 Drill Hammer with 4-1/2” x 21.5’ heavy wall lead steel with bit

8” IR QL80 Drill Hammer with 6” x 20’ lead steel with bit

4-1/2” X 25’ 2-7/8 API Drill Rod (11 pieces)

6” Casing Drive Plate

8” Casing Drive Plate

10” Casing Drive Plate

1 - Petol Chain Wrench set up for 4-1/2” Drill Rod and 6” Hammer

1 – Petol Chain Wrench set up for 6” Drill Rod and 8” Hammer

Lincoln Welder with Leads

Oxy/Acetalene Torch Setup

Located in Eastern Region

Note: Reduced Price as of June 2021

Rebuilt in 2006

Rebuilt Cummins KTA19C Diesel Deck Engine (rated 600 HP at 2100 RPM)

Rebuilt in 2006 a IRH2.5 1070 cfm / 350 psi air compressor

Deck Engine Meter Reads 5,955 hours

Mounted on a CCC (Crane Carrier)

Cummins L10 diesel engine

Carrier Meter Reads 4,635 hours

Carrier Meter Reads 22,353 Miles

50,000 lbs of pullback

Setup for 2-7/8" IF Drill Pipe

The following work was performed when rebuilt in 2006:

Rebuild of rig and components

Remanufactured Cummins engine KTA19C 600 HP @ 2100 RPM from Cummins

(upgraded from original 545 HP @ 2100 RPM)

Remanufactured IR compressor HR2.5 1070 CFM @ 350 PSI

Rebuilt funk box Rebuilt or new hydraulic pumps and motor

Rebuilt hydraulic cylinder All new hydraulics and air hose

New and upgraded radiator

New and upgraded air compressor, oil cooler and hydraulic oil cooler

Valve spool rebuilt – new seals and control handles

New feed chains upper and lower – Upgraded

New front leaf springs on carrier

New gauges

New wire harness

Rig and all parts sandblasted and painted grey and red

Rig completely serviced – Ready to drill

Additional tooling:

6” IR QL60 Drive Hammer with Bit

6” IR QL60 Drill Hammer with 4-1/2” x 21.5’ heavy wall lead steel with bit

8” IR QL80 Drill Hammer with 6” x 20’ lead steel with bit

4-1/2” X 25’ 2-7/8 API Drill Rod (11 pieces)

6” Casing Drive Plate

8” Casing Drive Plate

10” Casing Drive Plate

1 - Petol Chain Wrench set up for 4-1/2” Drill Rod and 6” Hammer

1 – Petol Chain Wrench set up for 6” Drill Rod and 8” Hammer

Lincoln Welder with Leads

Oxy/Acetalene Torch Setup

Located in Eastern Region

Specifications

| Manufacturer | Ingersoll-Rand |

| Model | T4W Drill Rig |

| Year | 1994 |

| Condition | Used |

| Stock Number | 15286 |

| Status | Sold |